Technology With Commitment

;

;

The new L12-X, including Switchable Guide Bush System allows the ‘best of both worlds’ for efficient machining of both long and short workpieces Flexible tooling options available including fixed and rotary tools for front \ back-machining as well as 0-90° adjustable angle rotary tool post. High speed 15,000RPM main spindle with 3.7kW motor - sub spindle 12,000RPM \ 1.5kW.

o ER8 5mm offset 1 station

o 3 position, 0-90° adjustable angle rotary tool post

o 10,000RPM 0.75kW

Number of axis - 7

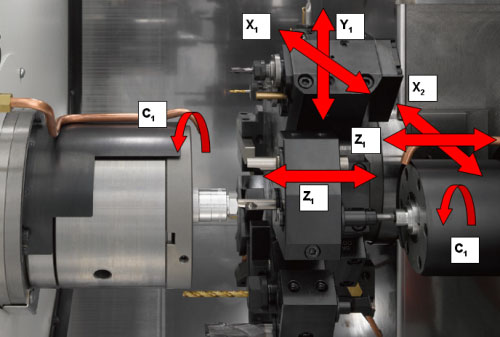

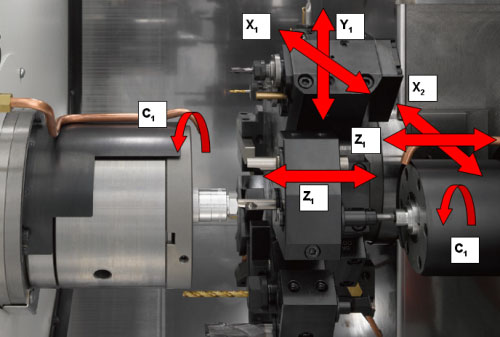

Acclaimed for its excellent cost to performance ratio, the A20 has evolved as a 7-axis machine for ø20 mm applications with the advantage that it can be used with or without a guide bushing. Use as a regular guide bushing automatic lathe when machining long, slender workpieces or without a guide bushing for shorter parts with minimal bar end remnants. The guide bushing can be quickly and easily mounted or removed.

The performance of the machine has been improved too. The high speed 10,000 rpm spindle enables optimized machining operations on smaller diameter bar material. The machining length per chucking is now extended to 200 mm enabling the number of re-chuckings and therefore cycle times to be reduced when machining long workpieces. As an option, bar material of up to ø25 mm can also be machined extending the range of workpieces.

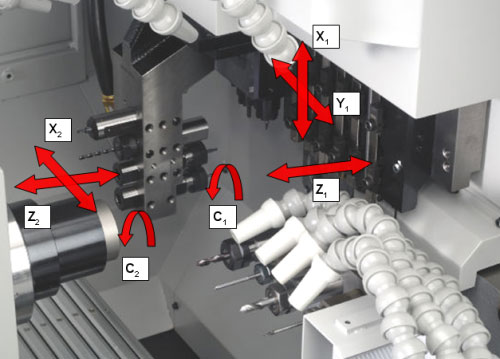

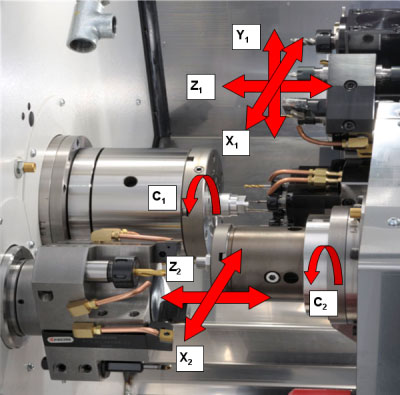

Number of axis - 10

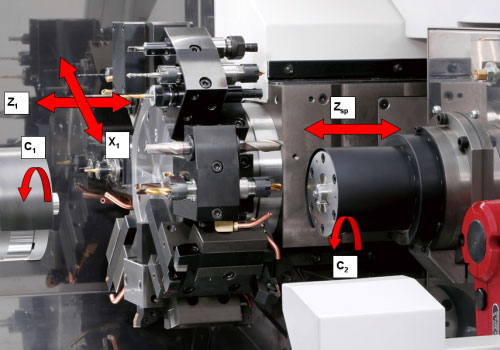

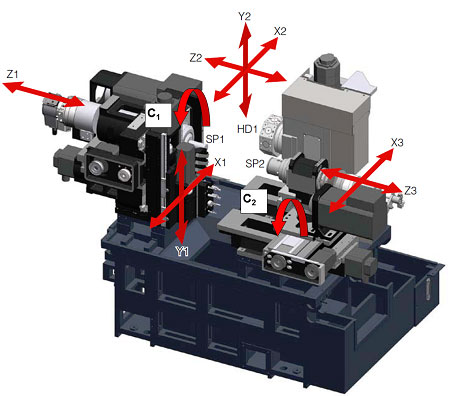

Introducing Citizen’s newest development, the D25 VIII, equipped with double gang tool posts and B axis. The double gang layout enables short cycle times for high productivity at low part cost. The large number of tools, for both main and sub spindle, gives cost effective production of complex workpieces.

Number of axis - 7

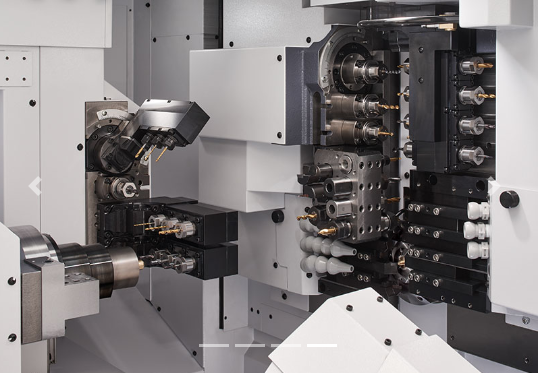

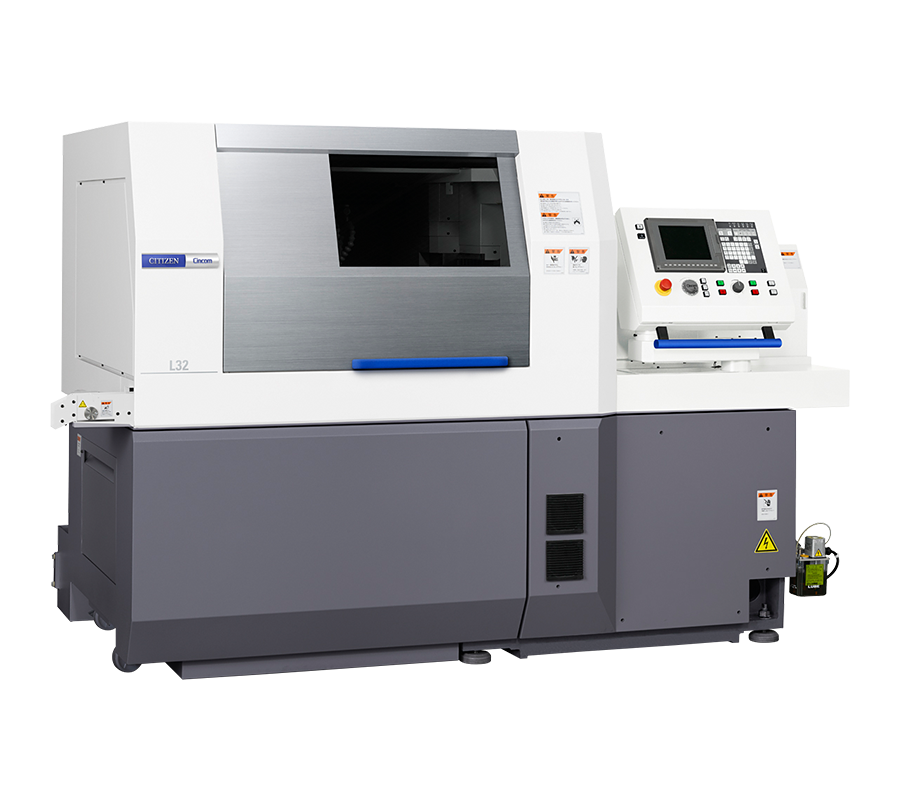

With a legacy as one of the best-selling Cincom machines, the next-generation L32 is launched with 3 models in modular design.

The L32-VIII is a 7-axis model with excellent cost performance. A wide range of modular tooling ensures that the new L32-VIII is both versatile and flexible enough to meet your production demands into the future.

Up to 30 tools can be mounted at any one time supported by a very high level of control features, stable, powerful, and highly productive with versatility of modular design.

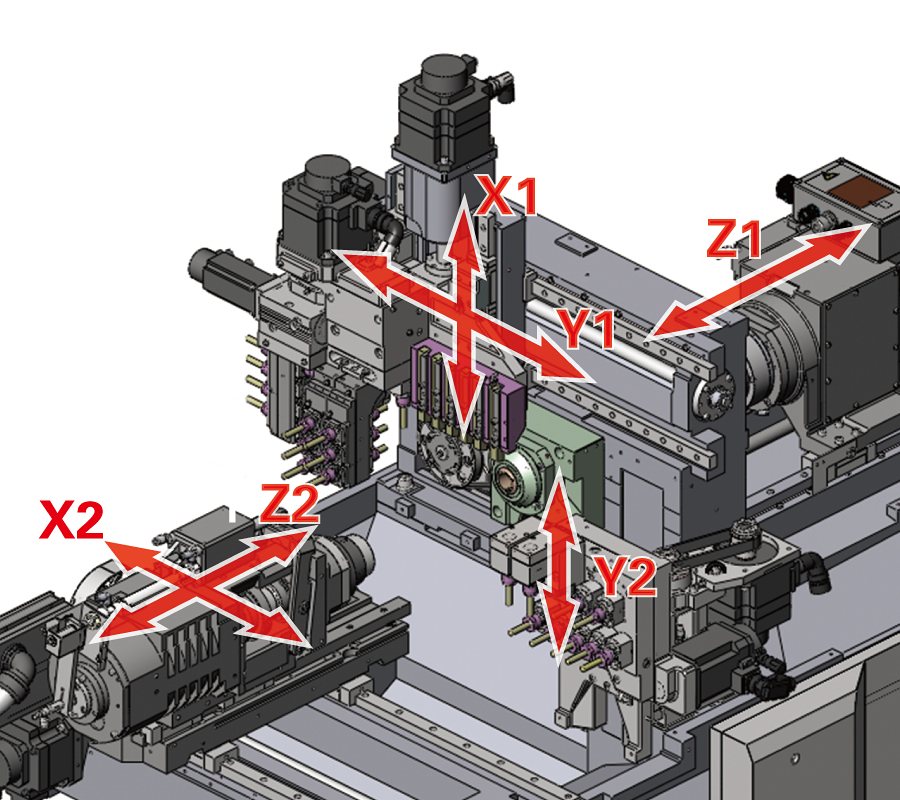

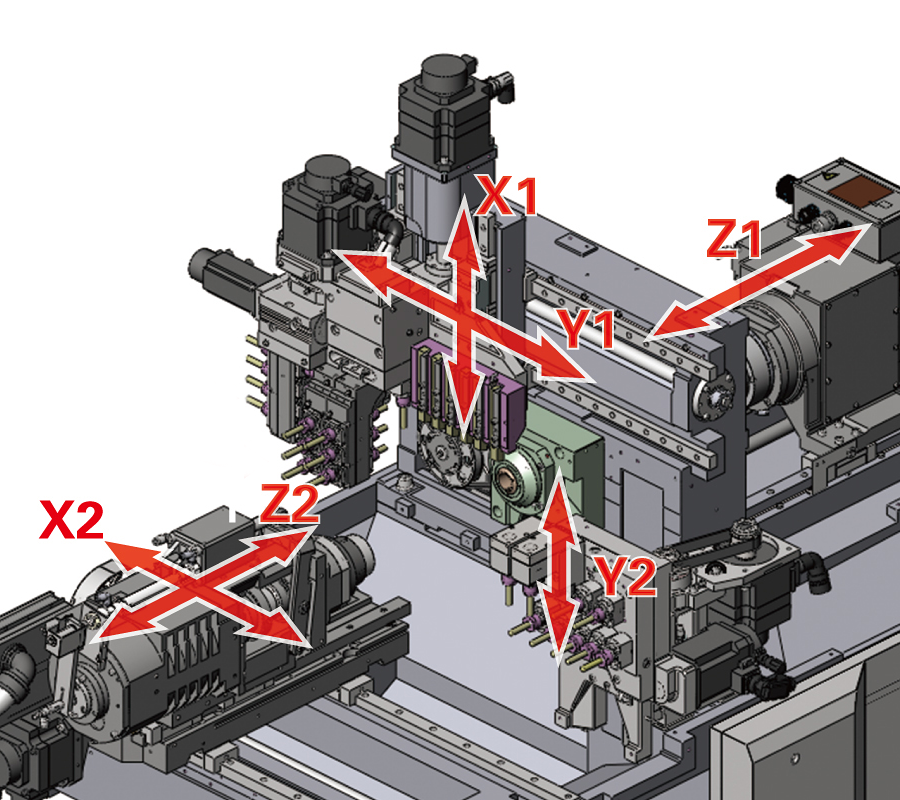

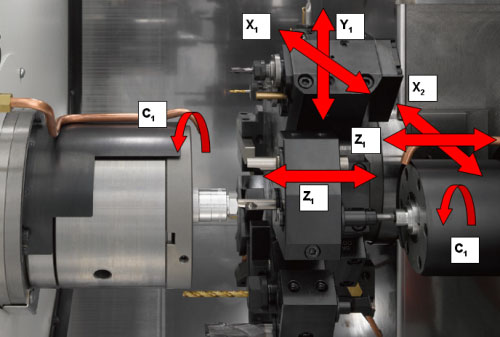

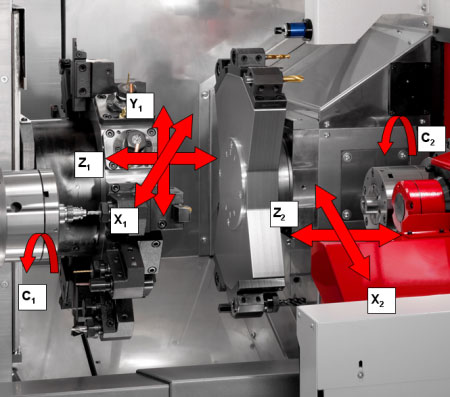

Number of axis - 8

With a legacy as one of the best-selling Cincom machines, the next-generation L32 is launched with 3 models in modular design.

The L32-X is an 8-axis model including two Y axis. A wide range of modular tooling ensures that the new L32-X is both versatile and flexible enough to meet your production demands into the future.

Up to 44 tools can be mounted at any one time supported by a very high level of control features, stable, powerful, and highly productive with versatility of modular design.

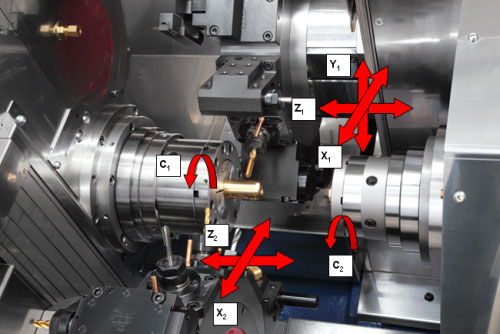

Number of axis - 9

With a legacy as one of the best-selling Cincom

machines, the next-generation L32 is launched with 3 models in modular design.

The L32-XII is a 9-axis model including two Y axis and B axis control. A wide range of modular tooling ensures that the new L32-XII is both versatile and flexible enough to meet your production demands into the future.

Up to 40 tools can be mounted at any one time supported by a very high level of control features, stable, powerful, and highly productive with versatility of modular design.

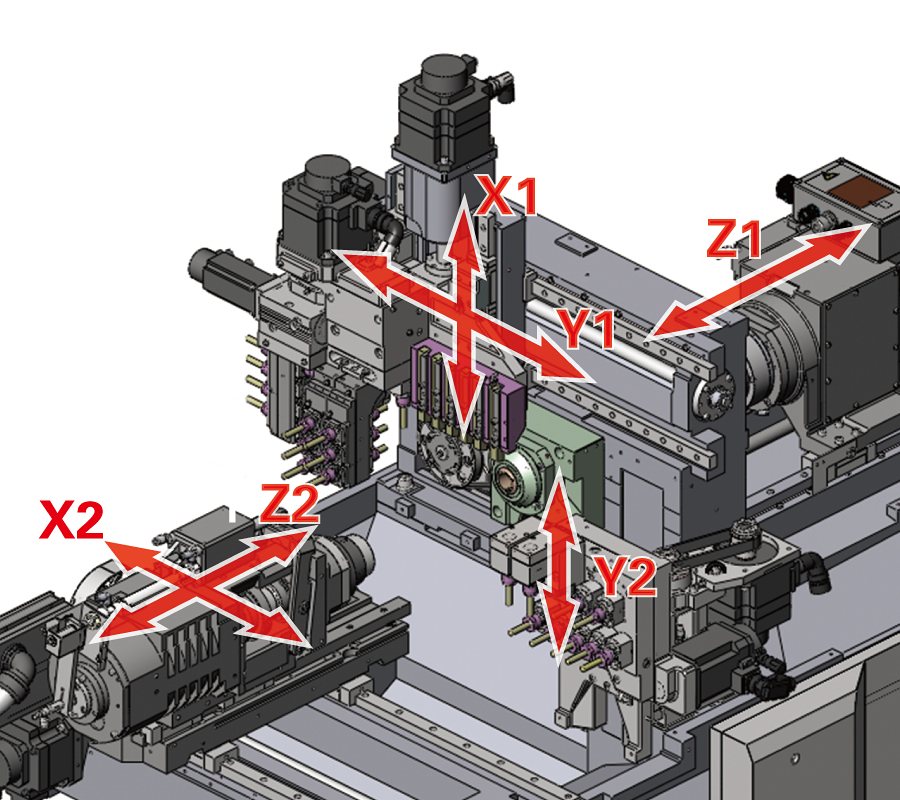

Cincom L3-20E type XII has been re-introduced with exciting new functions. The rotary tools on the gang tool post featuring B-axis control is now available with a 12 station automatic toolchanger. Allowing for drilling and milling of angle features. Contouring and milling of angled features in addition to contouring with full simultaneous 5-axis control. The swivel angle from 110°to -45° enables the B-axis to be used for front machining..

Another major feature is the ability to switch between a guide busing type and guide bushing-less type. This feature is provided as standard and the guide bushing can be fitted or removed very quickly with a simple operation.

Also featured is Y2 axis control on the opposite tool post for increased flexibility.

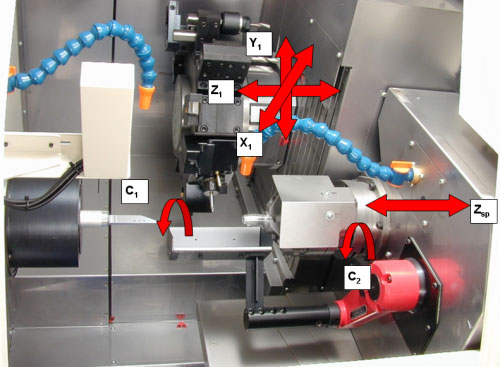

The new L12-VII, including Switchable Guide Bush System allows the ‘best of both worlds’ for efficient machining of both long and short workpieces

Flexible tooling options available including fixed and rotary tools for front \ back-machining as well as 0-30° adjustable angle rotary tool post.

High speed 15,000RPM main spindle with 3.7kW motor - sub spindle 10,000RPM \ 0.75kW.

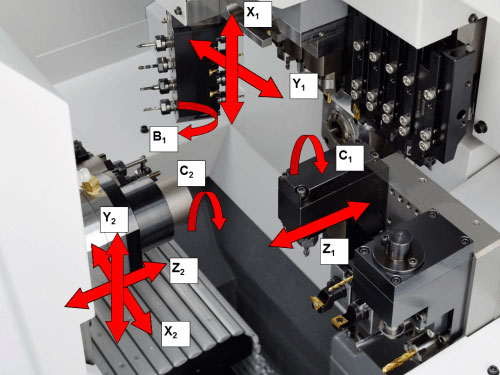

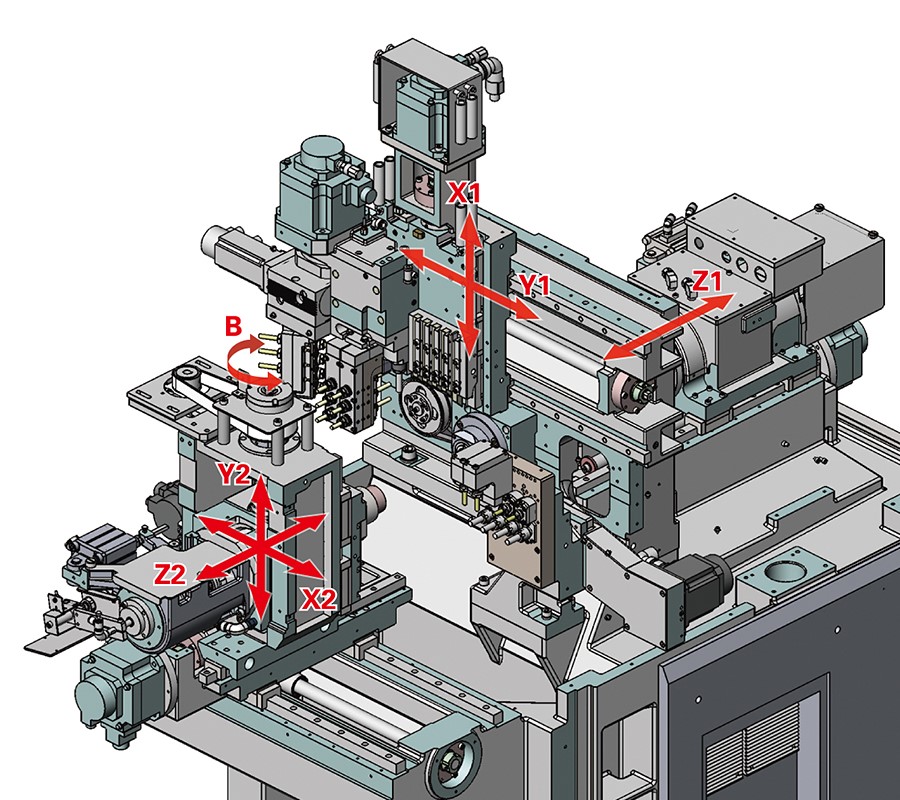

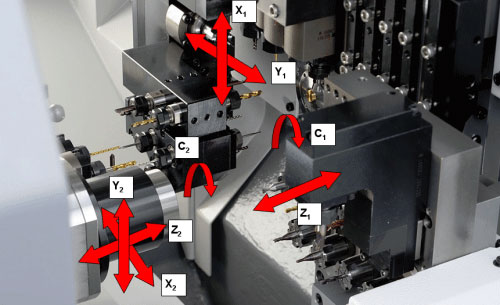

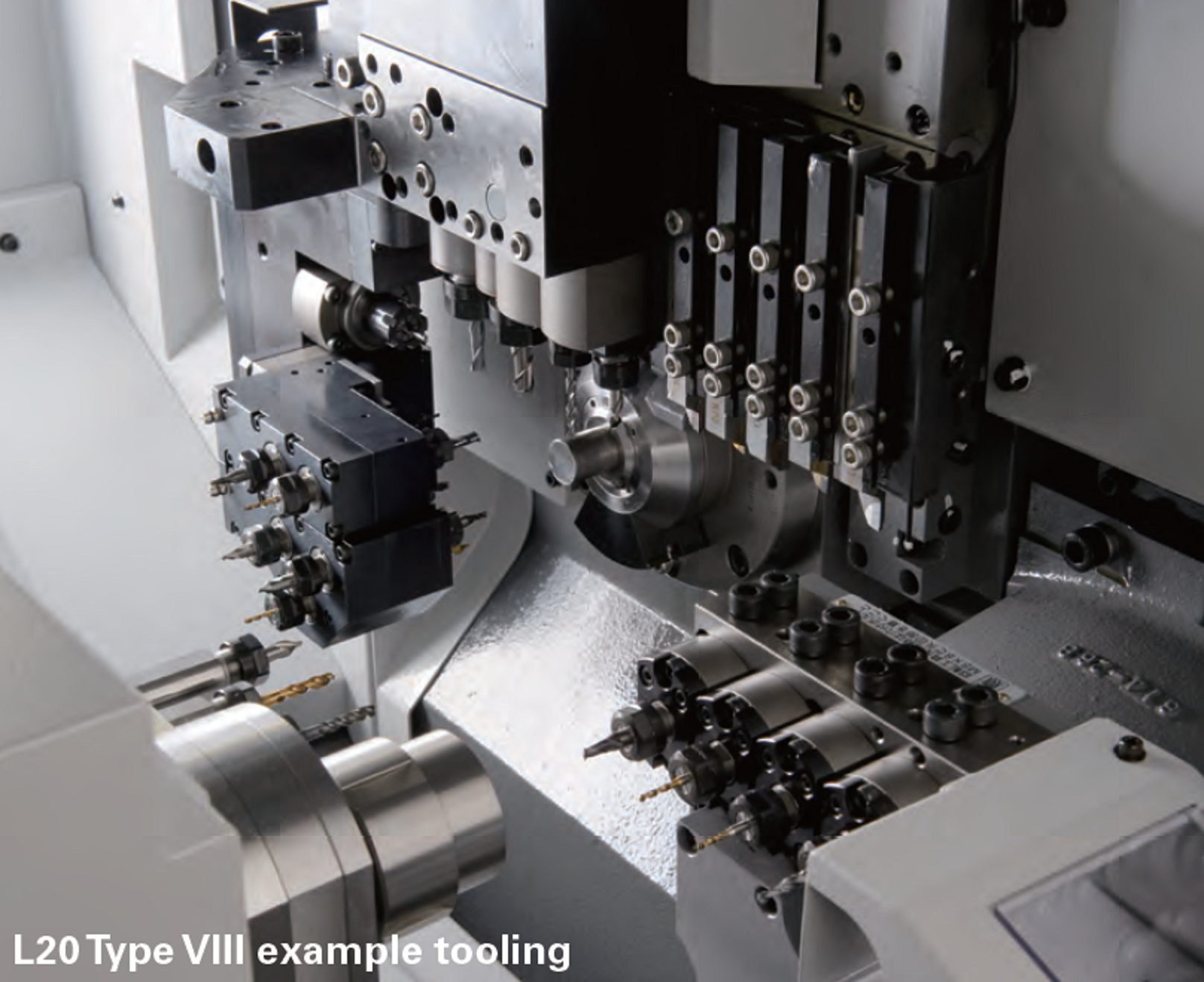

The L20 Series, synonymous with Cincom, has undergone a full model change. Productivity and versatility are realized with three easy-to-use tool posts: a horizontal “gang tool post” that eliminates chip entanglement, an “opposite tool post” perfect for simultaneous machining, and a “back tool post” dedicated to the machining of the back side. The LFV function for front and back machining and loader/unloader unit contribute to factory automation and labor savings.

Another major feature is the ability to switch between a guide bushing type and guide bushing-less type. This feature is provided as standard and the guide bushing can be fitted or removed very quickly with a simple operation.

Also featured is Y2 axis control on the opposite tool post for increased flexibility.

The L220X offers increased tool flexibility with up to 44 tools capability featuring 2 Y-axis.

The back working tool post utilizes Y-axis for up to 8 fixed or rotary, end-face or cross working tool holders for increased overlapping machining capability.

Another major feature is the ability to switch between guide bushing and guide bushing-less type. This feature is provided as standard; the guide bushing can be fitted or removed very quickly with a simple operation.

The user-friendly editing function which utilizes multi line, multi axis programming, along with superimosed and synchronized control make setting up the most complex jobs easy.

The L20 Series, synonymous with Cincom, has undergone a full model change. Productivity and versatility are realized with three easy-to-use tool posts: a horizontal “gang tool post” that eliminates chip entanglement, an “opposite tool post” perfect for simultaneous machining, and a “back tool post” dedicated to the machining of the back side. The LFV function for front and back machining and loader/unloader unit contribute to factory automation and labor savings.

Another major feature is the ability to switch between a guide bushing type and guide bushing-less type. This feature is provided as standard and the guide bushing can be fitted or removed very quickly with a simple operation.

The L20 Series, synonymous with Cincom, has undergone a full model changes with the addition of the new type XIIB5, which supports simultaneous 5-axis control. Productivity and versatility are realized with three easy-to-use tool posts: a horizontal “gang tool post” that eliminates chip entanglement, an “opposite tool post” perfect for simultaneous machining, and a “back tool post” dedicated to the machining of the back side. The B-axis function can be used for complex workpiece machining in advanced fields, the LFV function for front and back machining and loader/unloader unit contribute to factory automation and labor savings.

Another major feature is the ability to switch between a guide bushing type and guide bushing-less type. This feature is provided as standard, and the guide bushing can be fitted or removed very quickly with a simple operation.

Also featured is Y2 axis control on the opposite tool post for increased flexibility.

More tools!... more functions!... more flexibility!...higher productivity!... same floor space! Even greater value!

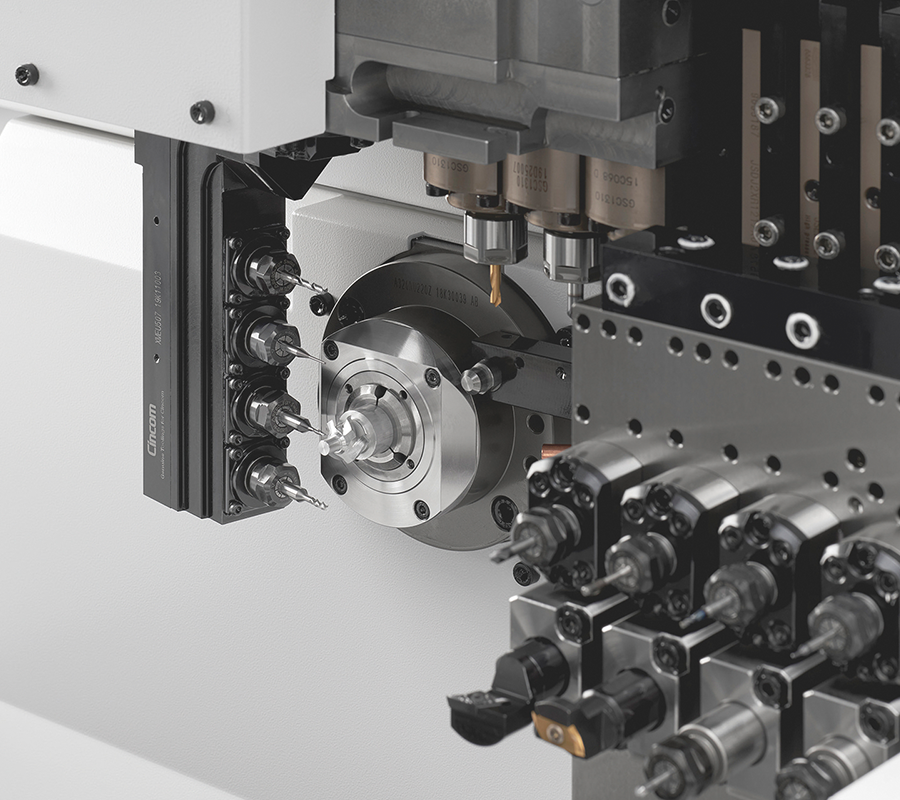

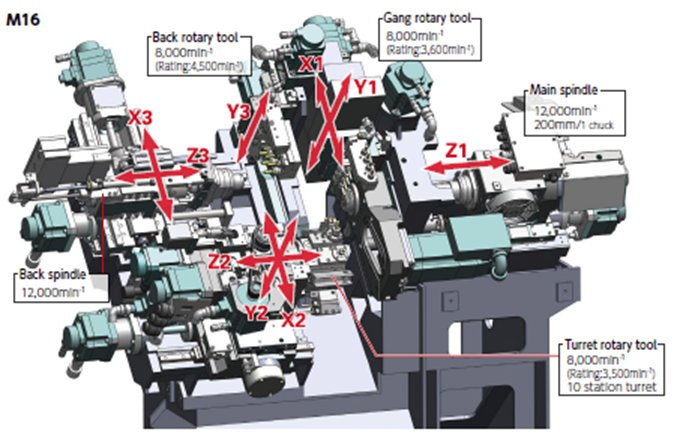

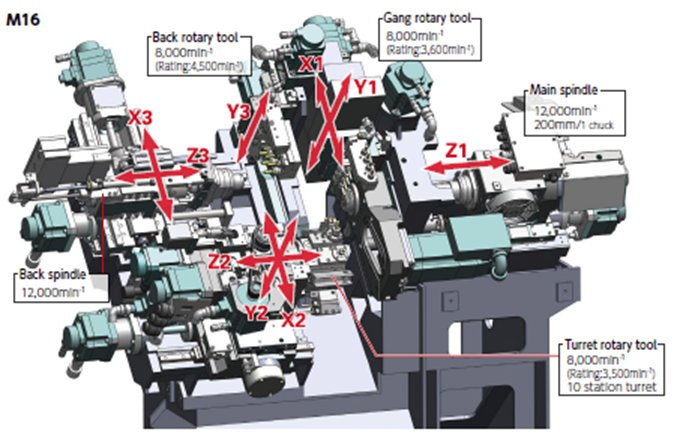

The M16 is renowned for its leading capability for 3 tool simultaneous machining in a compact floor space. The all round combination of flexible tooling, large tool capacity, and outstanding ease of use has made the M16 our success story in the new century. New advanced functions over the previous generation include an improved / upgraded turret with direct indexing, faster rapid feed rate (up to 32m/min) and reduced power consumption.

More tools!... more functions!... more flexibility!...higher productivity!... same floor space!

Even greater value!

The M16 is renowned for its leading capability for 3 tool simultaneous machining in a compact floor space. The all-round combination of flexible tooling, large tool capacity, and outstanding ease of use has made the M16 our success story in the new century. The next generation M16 increases the 3 tool simultaneous machining abilities with a new Y3 axis on the back tool post which carries up to 9 tools (up to 6 driven). New advanced functions include a B axis on the gang tool post with 4 axis simultaneous containing control. In addition the machine boasts an improved / upgraded turret with direct indexing, faster rapid feed rate (up to 32m/min) and reduced power consumption.

More tools!... more functions!... more flexibility!...higher productivity!... same floor space!

Even greater value!

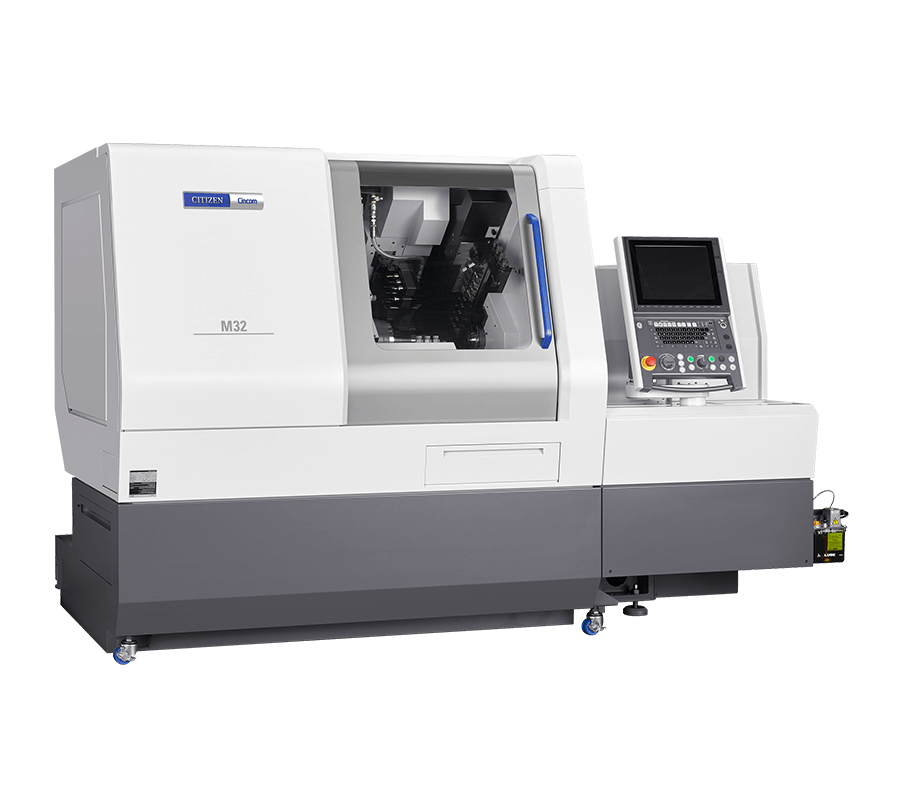

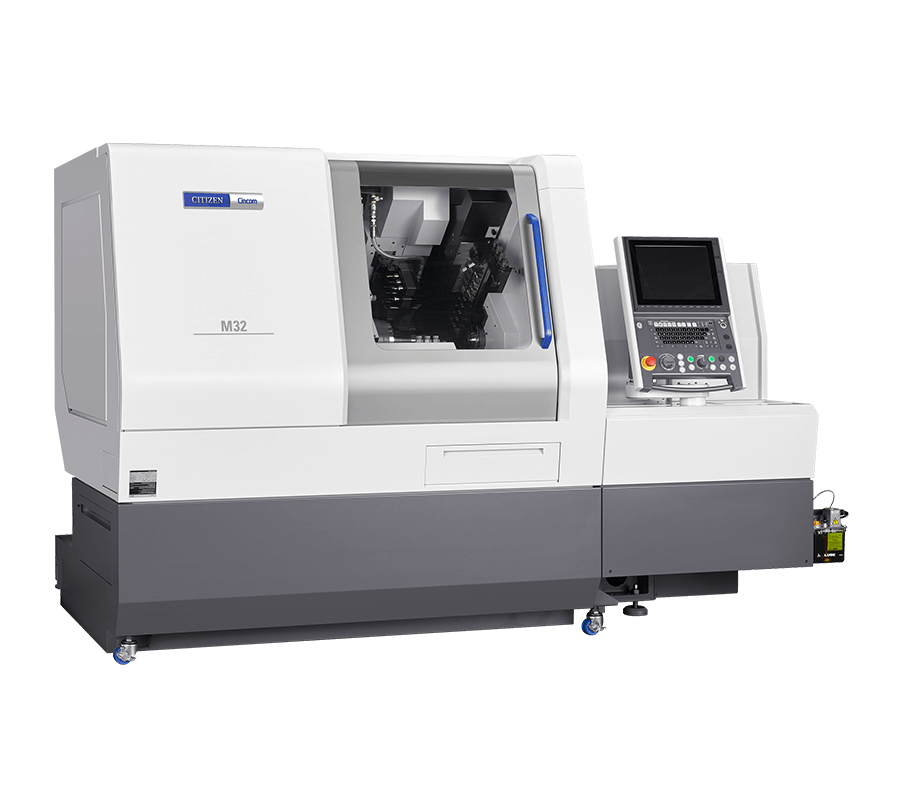

The M32 is renowned for its leading capability for 3 tool simultaneous machining in a compact floor space. The all round combination of flexible tooling, large tool capacity, and outstanding ease of use has made the M32 our success story in the new century. The next generation M32 increases the 3 tool simultaneous machining abilities with a Y3 axis on the back tool post which carries up to 9 tools (up to 6 driven). In addition, the machine boasts an improved / upgraded turret with adoption of single drive for rotary toolholders, fast rapid feed rate (up to 32m/min) and reduced power consumption

More tools!... more functions!... more flexibility!...higher productivity!... same floor space!

Even greater value!

The M32 is renowned for its leading capability for 3 tool simultaneous machining in a compact floor space. The all round combination of flexible tooling, large tool capacity, and outstanding ease of use has made the M32 our success story in the new century. The next generation M32 increases the 3 tool simultaneous machining abilities with a new Y3 axis on the back tool post which carries up to 9 tools (up to 6 driven). In addition the machine boasts an improved / upgraded turret with adoption of single drive rotary toolholders, fast rapid feed rate (up to 32m/min) and reduced power consumption.

More tools!... more functions!... more flexibility!...higher productivity!... same floor space! Even greater value!

The M32 is renowned for its leading capability for 3 tool simultaneous machining in a compact floor space. The all round combination of flexible tooling, large tool capacity, and outstanding ease of use has made the M32 our success story in the new century. In addition the machine boasts an improved / upgraded turret with direct indexing, faster rapid feed rate (up to 32m/min) and reduced power consumption.

More tools!... more functions!... more flexibility!...higher productivity!... same floor space!

Even greater value!

The M32 is renowned for its leading capability for 3 tool simultaneous machining in a compact floor space. The all round combination of flexible tooling, large tool capacity, and outstanding ease of use has made the M32 our success story in the new century. The next generation M32 increases the 3 tool simultaneous machining abilities with a new Y3 axis on the back tool post which carries up to 9 tools (up to 6 driven). In addition the machine boasts an improved / upgraded turret with direct indexing, faster rapid feed rate (up to 32m/min) and reduced power consumption.

The Cincom sliding head lathe R07 defines it's own category for ultra-precise production of small and tiny parts. Equipped with a sub spindle and 2 rotary tools the machine is designed for maximum precision, extremely fast machining, short response times whilst occupying minimal floor space.

Bar profiles round, hexagonal, square

Maximum bar length 13'

Bar stabilization Oil supply to the guide rail. Intermediate three-roller support and rear-end four roller support. Attached with an oil splash prevention guide rail shutter.

Bar rack width 10.25"

Control Operation and synchronous control by NC lathe

Power source AC200/220V, 50/60Hz

Weight (without oil) 1,254 - 1,430 lbs

Bar diameter range

2 ~ 16mm (CAV16)

2 ~ 20mm (CAV20)

2 ~ 25mm (CAV25)

3 ~ 36mm (CAV32)

Oil ISO VG68

Cincom’s unique bar and spindle stabilizing mechanism aligns precisely the bar’s center of rotation with the center of the spindle. Forces are evenly distributed, protecting the spindle from excessive wear.

As the bar rotates, it becomes hydrostatically supported in a bath of oil, and perfectly centered in the guide channels. Even with full-length, 13' bars, the lathe can operate noise-free and vibration-free at speeds to 12,000 rpm.

Movements of the bar feeder are automatically programmed as an additional Z-axis on the turning center’s CNC. All bar feeder movements mirror exactly the movements in the lathe. The result is superior precision and maximized productivity.

An auxiliary device pre-positions the bar. Forward and back motion is controlled by a servo that's connected directly to the lathe’s CNC. The bar positions to tenths accuracy with no following error. Insertion and braking response times are instantaneous.

Bar profiles round, hexagonal, square

Maximum bar length 12' for 1.5mm - 1.6mm bar. 6' max for 1mm - 1.4mm bar

Bar stabilization Oil supply to the guide rail. Intermediate four-roller support and rear-end four roller support. Attached with an oil splash prevention guide rail shutter.

Screw Type Bar Separator standard screw guide will hold 12 bars, 16mm screw guide will hold 9 bars 4mm screw guide will hold 24 bars

Control Operation and synchronous control by NC lathe

Power source AC200/220V, 50/60Hz

Weight (without oil) 1,144lbs

Bar diameter range

1mm ~ 12mm (CAV12-LE)

Oil ISO VG32

Cincom’s unique bar and spindle stabilizing mechanism aligns precisely the bar’s center of rotation with the center of the spindle. Forces are evenly distributed, protecting the spindle from excessive wear.

As the bar rotates, it becomes hydrostatically supported in a bath of oil, and perfectly centered in the guide channels. Even with full-length, 13' bars, the lathe can operate noise-free and vibration-free at speeds to 12,000 rpm.

Movements of the bar feeder are automatically programmed as an additional Z-axis on the turning center’s CNC. All bar feeder movements mirror exactly the movements in the lathe. The result is superior precision and maximized productivity.

An auxiliary device pre-positions the bar. Forward and back motion is controlled by a servo that's connected directly to the lathe’s CNC. The bar positions to tenths accuracy with no following error. Insertion and braking response times are instantaneous.

The two pusher system drastically reduces the overall length of the unit by as much as 4 feet. A short pusher pre-feeds the bar then retracts, then a second full-length pusher lowers into position to continue the feeding process.

Dual anti-vibration devices stabilize the bar stock at two critical points between the guide channel and lathe spindle maximizing RPM potential. Its adjustable roller design provides superior support and easy setup of all bar diameters without the cost of multiple bearing blocks.

Optional bushing-blocks replace rollers on out-board steady rest when running shaped stock.

The gripper device holds and inserts the new bar into the bar collet and is also used to extract the remnant. Bar ends that are free of burrs require no additional chamfering. The gripper requires no adjustment for bar size changes as it “self-centers”.

The bar pusher is equipped with a standard rorating tip that ensures smooth running at high RPM. The bar stock collet is a common thread-on or pin-on type.

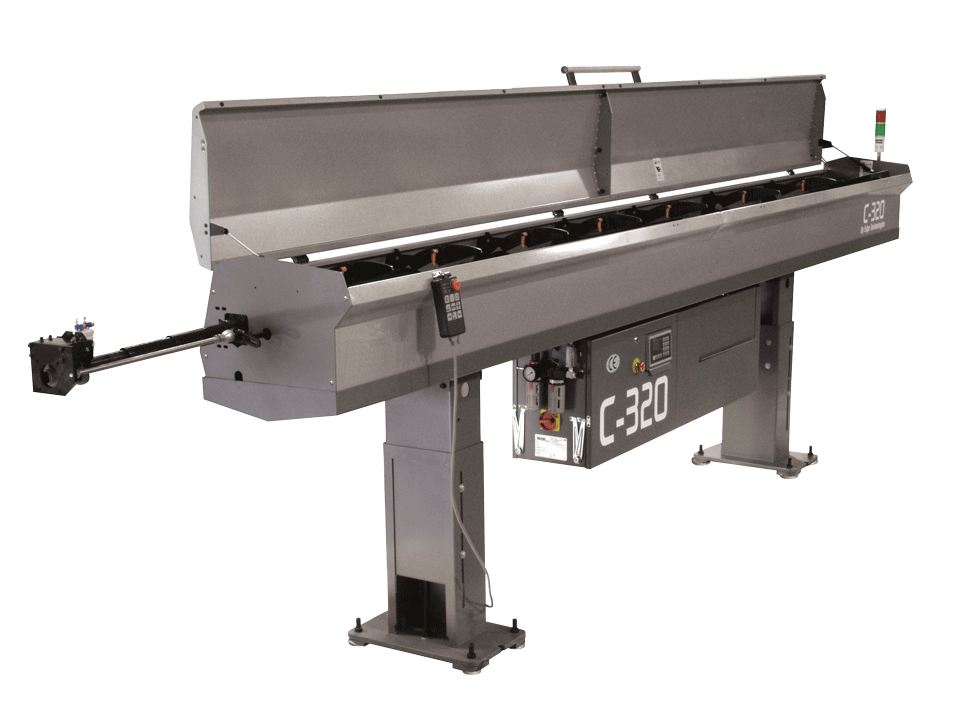

As a standard feature on the C320/C332, the Synchronization device for Swiss style lathes employs an electro-magnetic coupling, mechanically linking the lathes headstock’s z-axis travel to the bar feeder’s pusher to ensure synchronous movement and no loss of connection between the bar stock and collet-pusher. The bar remnant is withdrawn to the back end of the magazine. A gripper extracts it from the bar stock collet and deposits it in a hide-away remnant basket.

The C320/C332’s double pusher system is propelled by a toothed belt for accuracy as well as smooth quiet running.

A Mitsubishi controller and servo drive provide the Minuteman’s motion control and functionality.

The C320/C332 features the convenience of an easy-to-use remote control pendant. Functions include:

The top guide channel is profiled for all bar stock sizes. The “U” shaped bottom guide channel sections slide easily out of their base. Simply insert the new channel size, tighten the screw and the C320/C332 is ready for the new bar stock.

The control is easy to program, yet flexible enough for all applications. Parameters are set through simple F functions. Alarms are well defined and displayed on the operator control panel. Panel swings out for ease of use.

Heavy gauge structural steel ensures rigidity and long term durability.

The bar stock magazine is an incline rack with a loading capacity of 10 linear inches. Bars can be loaded from the front or the rear sides of the bar feeder.

The bar stock alignment guides are quickly and easily adjusted for different bar diameters, effectively reducing set up time.

The channel is flooded with oil to create a hydrodynamic effect resulting in higher RPM with reduced noise and vibration.

Power consumption - 1.5 kW

Feed force - adjustable, max. 450 N

Forward feed rate - adjustable max. 600 mm/sec

Return feed rate - 1000 mm/sec

Loading time - 30 sec (for 12 ft. bars)

Oil capacity - 46 liters (12 gallons)

Oil viscosity - ISO 100 cST

Operating voltage - 230 V/60 Hz

Compressed air supply - 6 bar (90 psi)

Compressed air consumption - approx. 8 liters per loading action

Weight without oil - 1320 lbs

Remnant length - 420mm max (16.5 inches)

Maximum Bar Length - 3785 mm (12’5”)

Bar Diameter Range - 3-26 mm (.125“-1.023“)

Reversible Configuration - Machine is reversible to load material from front or rear

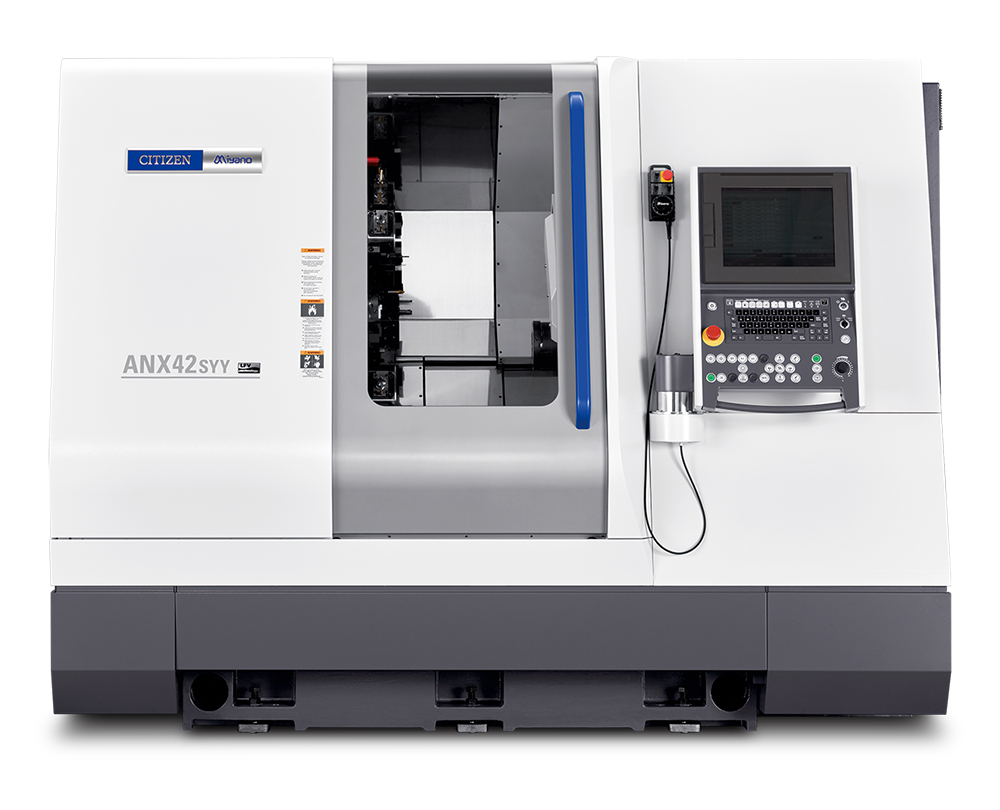

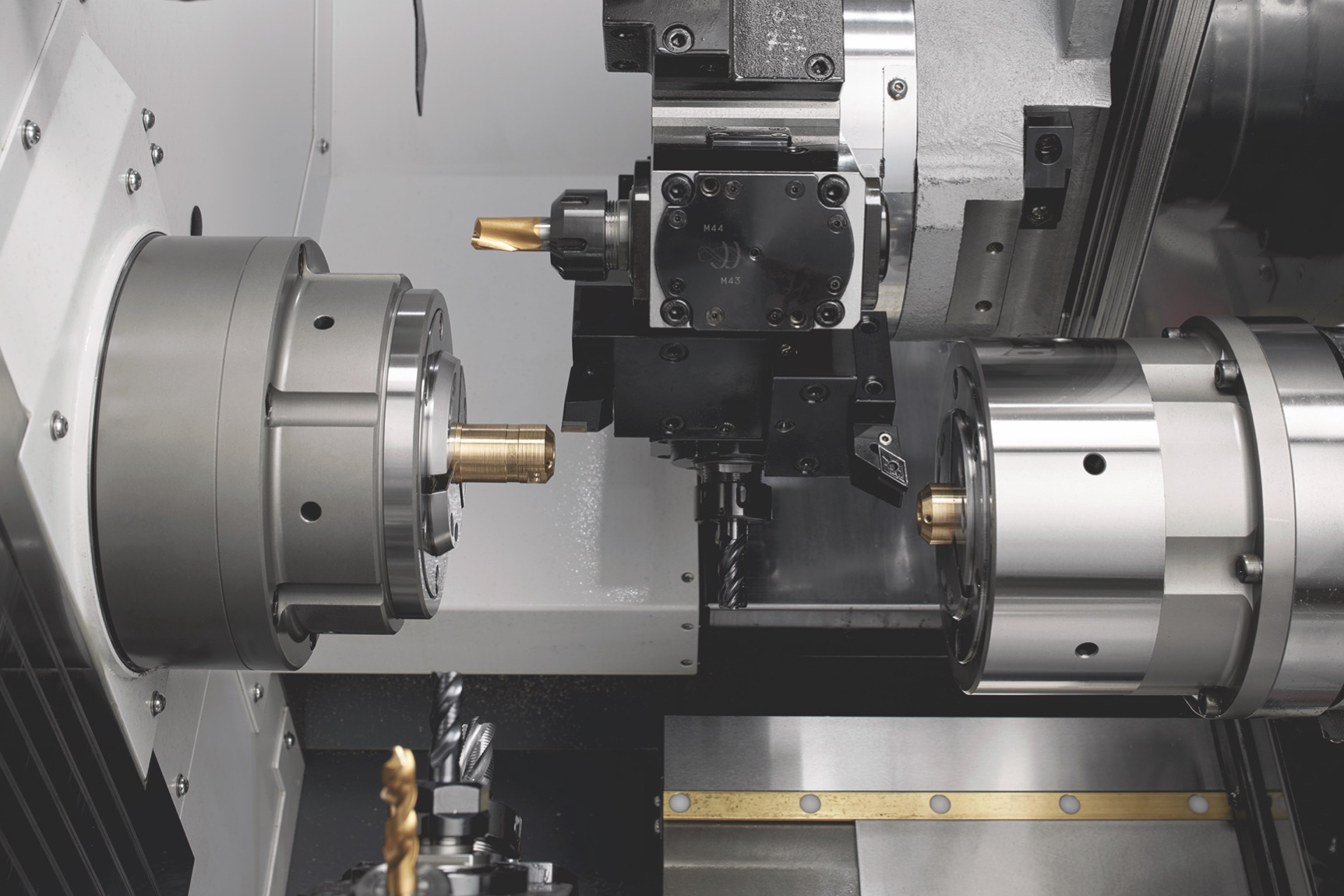

The new ANX-42MSYY series machine is capable of up to 42mm bar capacity. With a Y-axis on the upper and lower turret, increased opportunities for simultaneous machining is possible. Both turrets have 12 stations and any station can accept live tools. The X-axis on the sub spindle provides the ability to have 3 tools cutting at the same time. Operator/Programmer interaction with the machine is greatly enhanced with the new 15" Fanuc series, touch screen control. The machine is also capable of utilizing Low Frequency Vibration Technology.

This machine, developed based on the best-selling BNJ series under the Miyano brand, has inherited the characteristics of the Miyano brand in terms of the highly rigid basic configuration and hand scraped slideways, and demonstrates stable machining accuracy. In addition to that, even larger and longer workpieces can be handled thanks to the extended stroke of the X1 axis, increased capacity of the servomotor, extended stroke of the X2 axis, and increased back spindle chuck size. By adopting a Mitsubishi control, highly efficient machining is achieved through a wealth of machining support functions and superimposition machining, which is the biggest feature, in combination with the excellent operability cultivated under the Cincom brand

Entry level value with back machining flexibility.

Featuring 2 spindles and 1 turret, the entry-level BNA-42S offers excellent value for simpler requirements whilst offering back machining abilities.

Featuring 2 spindles, Y-axis equipped turret and an X2 axis on the back spindle, the BNA-42MSY offers excellent value with independent machining on the front and back of the workpiece simultaneously. This, in effect provides the benefits of a twin-turret model with the significant cost savings of a single turret model.

Featuring 2 spindles, Y-axis equipped turret and an X2 axis on the back spindle, the BNA-42MSY offers excellent value with independent machining on the front and back of the workpiece simultaneously. This, in effect provides the benefits of a twin-turret model with the significant cost savings of a single turret model.

The new BNE-MYY series machine is available in both a 51mm and 65mm bar capacity. With a Y-axis on the upper and lower turret, increased opportunities for simultaneous machining is possible. Both turrets have 12 stations and any station can accept live tools. The X-axis on the sub spindle provides the ability to have 3 tools cutting at the same time. Operator/Programmer interaction with the machine is greatly enhanced with the new 15" Mitsubishi 800 series, touch screen control.

Featuring 2 spindles, Y-axis equipped turret and flexible gang toolslide, the BNA-42GTY offers excellent value with independent machining on the front and back of the workpiece simultaneously.

Featuring 2 spindles and 1 turret (with Y axis function) the BND-51SY2 enables rapid processing of complex workpieces. All main turret stations are driven (max 2.5kW, 4000rpm). Complex machining is possible using the Y-axis slide.

Maximum bar length 12' 6"

Bar Diameter Range 5-42 mm

Loading Time 30 sec (for 12' bars)

Bar supply method Disk feeding

Control Operation and synchronous control by NC lathe

Operating Voltage 220~230 V/60hz

Weight (without oil) 2100 lbs.

Oil ISO VG68/351(M16) ISO VG68/451(L20/M20)

12 linear inched of rack capacity

Universal polyurethane guide channels handle a wide range of stock sizes, yet change over quickly. The channel is flooded with oil to create a hydrodynamic effect resulting in higher RPM with reduced noise and vibration.

Heavy gauge sturctural steel ensure rigidity and long term durability

The control is easy to program, yet flexible enough for all applications. Memory storage for jobs simplifies changeovers. Diagnostics and troubleshooting are all run from this advanced control screen.

A reliable, universal Mitsubishi motion control - dependable and user friendly. Allows easy bar feeder parameters.

Bar diameter capacity: 5 mm to 67 mm (.196” to 2.63”)

Bar length capacity: up to 60”(spindle length determines maximum bar length)

Magazine capacity is 25 linear inches

Mitsubishi PLC controller—powerful & user friendly

Easy centerline adjustment using sliding scale

Standard x-axis axial shift device

Soft load material presentation

Remote control pendant

12 linear inched of rack capacity

Fixed piece feed-out and sub-spindle mode

Lathe spindle speed can be maximized

Material length can be uniform or random

Material can be round, hexagonal or shaped

(3) Pushers included: 6 mm, 12 mm, 19 mm

Maximum bar length 12' 6"

Bar Diameter Range 5-42 mm

Loading Time 30 sec (for 12' bars)

Bar supply method Disk feeding

Control Operation and synchronous control by NC lathe

Operating Voltage 220~230 V/60hz

Weight (without oil) 2100 lbs.

Oil ISO VG68/351(M16) ISO VG68/451(L20/M20)

12 linear inched of rack capacity

Universal polyurethane guide channels handle a wide range of stock sizes, yet change over quickly. The channel is flooded with oil to create a hydrodynamic effect resulting in higher RPM with reduced noise and vibration.

Heavy gauge sturctural steel ensure rigidity and long term durability

The control is easy to program, yet flexible enough for all applications. Memory storage for jobs simplifies changeovers. Diagnostics and troubleshooting are all run from this advanced control screen.

A reliable, universal Mitsubishi motion control - dependable and user friendly. Allows easy bar feeder parameters.

– CAV42: 5mm to 42mm (.196” to 1.653”)

– CAV51: to 51mm (2”).

Bar diameter capacity: 5 mm to 67 mm (.196” to 2.63”)

Bar length capacity: up to 60”(spindle length determines maximum bar length)

Magazine capacity is 25 linear inches

Mitsubishi PLC controller—powerful & user friendly

Easy centerline adjustment using sliding scale

Standard x-axis axial shift device

Soft load material presentation

Remote control pendant

12 linear inched of rack capacity

Fixed piece feed-out and sub-spindle mode

Lathe spindle speed can be maximized

Material length can be uniform or random

Material can be round, hexagonal or shaped

(3) Pushers included: 6 mm, 12 mm, 19 mm

The compact manual fiber laser marking machine FOBA M1000 has been designed for the high-quality laser marking of small parts, medium sized components and work pieces and batches. Among others, the M1000 is ideally suited for laser marking autoparts, medical products, metal and plastic tools and general industrial products and components. The small and mobile universal marking workstation is also perfect for laser based contract manufacturing. The M1000 processes small metallic and plastic components but also batches both economically and in high marking quality.

It is ideally suited for manufacturers with low volume requirements or where space constraints demand an efficient solution. The workstation can also be cart mounted for mobility throughout a user's facility.

The desktop workstation is operated in laser safety class 1 and comes with a programmable Z-axis, a small worktable and a smoothly opening lift door – available either as manual or as optional electric lift door. When open, the interior space is accessible from three sides. In order to cover the broadest possible spectrum of applications, various fiber laser markers are available for integration.

The M-Series represents FOBA's next-generation of laser marking machines. The M-Series laser workstations process small, large and geometrically complex work pieces as well as batches and small series precisely and efficiently. The M-Series is available in two housing sizes (M2000 and M3000), and three models for each size (B: with work table, R: with rotary table, P: with X/Y/Z axis).

The M2000-Blaser marking machine is equipped with a programmable Z-axis, a work table and an electric lift door. The general-purpose laser marking machine marks various single parts including large ones) in many sectors, including the automobile industry, the construction of metals, tools and machines, the medical field and plastic-processing industries.

The M2000-P laser workstation is equipped with three programmable axes (X, Y, Z; can be expanded to 5 axes) and an electric lift door. The laser workstation is ideally suited for the processing of batches and the small parts in pallets; the M2000-P has also been designed to mark larger components for which the marking positions have to be travelled at or where marks have to be applied at several positions.

The M2000-R automatic rotary table machine is equipped with a programmable Z-axis and a 2-station rotary table. It is ideally suited for the production of serial parts found in day/night design elements, metal components, tools or medical products.

The M-Series represents FOBA's next-generation of laser marking machines. The M-Series laser workstations process small, large and geometrically complex work pieces as well as batches and small series precisely and efficiently. The M-Series is available in two housing sizes M2000 and M3000), and three models for each size (B: with work table, R: with rotary table, P: with X/Y/Z axis).

The M3000-B laser marking machine is equipped with a programmable Z-axis, a work table and an electric lift door. The all-purpose laser workstation is particularly useful when it comes to the marking of large single parts in many sectors, including the automobile industry, the construction of metals, tools and machines, the medical field and plastic-processing industries.

The M3000-P laser workstation is equipped with three progrannable axes (X, Y, Z; can be expanded to 5 axes) and an electric lift door. The laser workstation is ideally suited for the processing of batches and small parts in pallets and trays; the M3000-P has also been designed to mark larger components for which the marking positions have to be traveled at, or where marks have to be applied at several positions.

The M3000-R automatic rotary table workstation is equipped with a motor-adjustable Z-axis and a 2-station rotary table. It is ideally suited for the production of serial parts found in day/night design elements, metal components, tools or medical products.