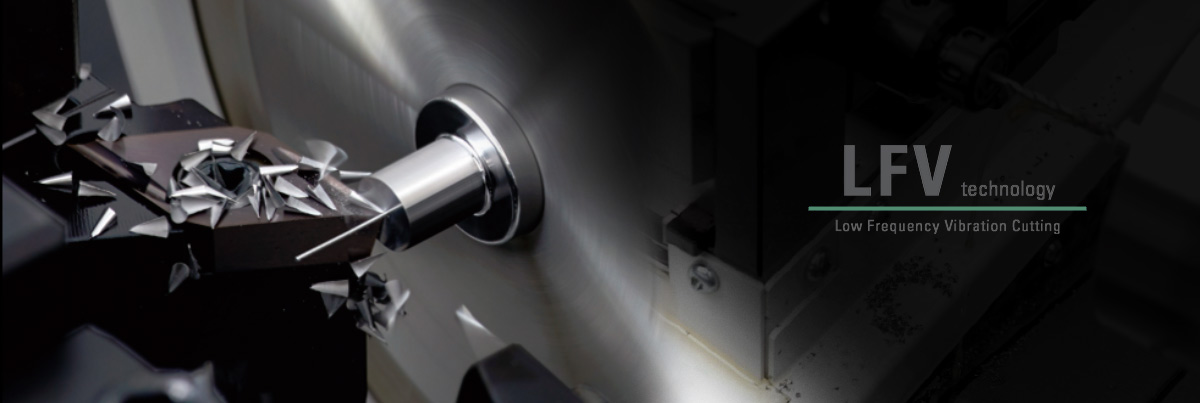

LFV

What is LFV

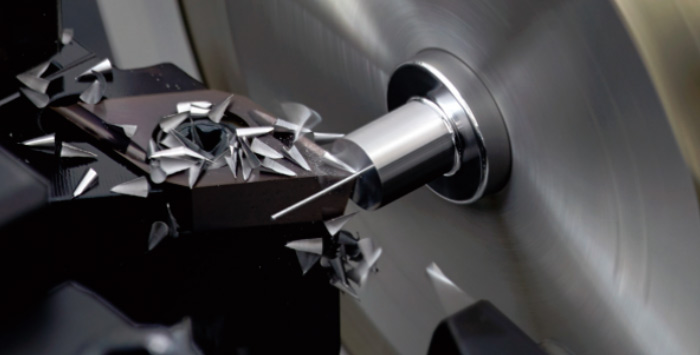

The servo axes are vibrated in the axial direction using a unique control technology whereby cutting is performed while synchronising this vibration with the rotation of the spindle.

Because “air-cutting” times are provided during cutting, this technique is also characterised by intermittent expulsion of fine chips. This has made it possible to resolve problems such as chip entanglement and built-up edges at a stroke.

Vibration cutting can handle a variety of types of machining in addition to linear machining on faces, including tapers, arcs, and drilling across a wide range of machining geometries and materials.

Vibration cutting can be turned ON and OFF just by inserting G codes in machining that has proved difficult up until now, such as the machining of deep holes and micro-machining.

Citizen LFV Cutting Technology – Reduced Chip Sizes

`Citizen's Enhanced Low Vibration Cutting (LFV) Technology

Citizen's Low Vibration Cutting (LFV) Technology

-

*Reduction of down-time/increase in productivity and profit

*Efficiency Through a combination of vibration and Standard-cutting

*Very fine work pieces are possible

*Excellent for deep hole drilling